INSERT-1718

This INSERT supplements the Aerocoupe Assembly Manual when building with parts from the Everything Else Kit.

Get ANSWERS! and help others

If the printed Assembly Manual + THIS INSERT leaves you unclear how to complete a step in the build process, please first check the instructions at SHIFTev.com for the specific part number that you're having difficulty with.

Here's how:

- Navigate through the SHIFTev.com web catalog to the part you have questions about. Links to detailed instructions are often included.

- Or enter the part number in the Search box at the top of any page on SHIFTev.com. Depending on your display size, you may need to scroll to see the search results.

- If those options don't resolve your question, contact us and we'll do our best to help you first, AND then help others by revising this insert.

Start with the latest version!

Thanks to our customers, this INSERT is constantly improving. Naturally, it's best to use the latest revision of this INSERT at SHIFTev.com. If you're reading a print, confirm it's the latest version by searching SHIFTev.com for "INSERT-1718" in the Search box at the top of any page. Depending on your display size, you may need to scroll to see the search results. Compare revisions found on the last page.

TOPICS ARE NOT LISTED IN ANY PARTICULAR ORDER:

1. Throttle pedal mountingSHIFT EV supplies a throttle foot pedal with a threaded pivot shaft at its base. Simply drill a pivot hole for the pedal shaft to slip through. The hole can be on the front frame tube or a bracket you add. The exact pedal location & mounting is up to the builder because the ideal position varies greatly based on driver size. SHIFT EV includes a throttle cable with housing and cable clamping screw assemblies for both ends of the throttle cable. The stiff angle cable mounts (to the body or frame) are not supplied, because they can easily be made from scrap angle iron, shelf brackets, or other basic materials. The crude drawing below is intended to give you the very basics of how the mechanical throttle controls can be assembled.

Send us a better visual explanation and we'll credit your team for it!

Send us a better visual explanation and we'll credit your team for it!

Is your POT box is miss-behaving? Video: How to check your POT Box and how to properly adjust it if needed.

OR, skip the pot-box + cable + pedal altogether, and go with a Throttle input like twist grip (part#1312) or Thumb throttle (part#1887).

2. Battery fit

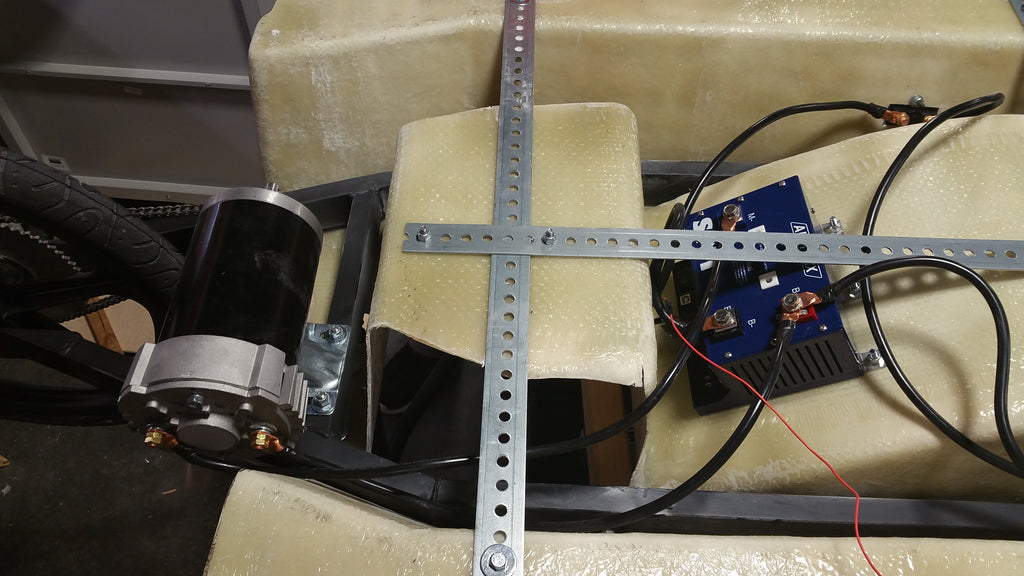

The base of the fiberglass battery box is slightly too small to accept “all” of the authorized batteries. If the batteries you received do not fit well at the base, the fiberglass may be trimmed. Trimming and reinforcement have been done in many ways. This image is offered as an example of how one team went about it. We don’t recommend placing the controller at the location shown, because it is so exposed to the elements and difficult to service. See step 7 in the Aerocoupe manual for where to locate the controller.

Send us a better visual explanation and we'll credit your team for it!

OR, skip the pot-box + cable + pedal altogether, and go with a Throttle input like twist grip (part#1312) or Thumb throttle (part#1887).

2. Battery fit

The base of the fiberglass battery box is slightly too small to accept “all” of the authorized batteries. If the batteries you received do not fit well at the base, the fiberglass may be trimmed. Trimming and reinforcement have been done in many ways. This image is offered as an example of how one team went about it. We don’t recommend placing the controller at the location shown, because it is so exposed to the elements and difficult to service. See step 7 in the Aerocoupe manual for where to locate the controller.

Send us a better visual explanation and we'll credit your team for it!

3. No Chain Ring Required

The Aerocoupe Assembly Manual suggests using bicycle sprockets and bicycle chain which isn’t included in the kit ordered from SHIFT EV. Bicycle systems stretch and more easily de-rail under the heavier loads and up-right configuration during corners in competitions. The Assembly Manual produced by the chassis manufacturer refers to a "Chain Ring" assembly to help the bicycle chain from de-railing. SHIFT EV ships the chassis kit without the chainring because it’s not needed. We've instead provided a superior drive system of go-kart sprockets and chains which are designed for rigorous loads and cornering - without derailing. We’ve also included 3 different sized motor sprockets to help you find the optimal drive ratio. You may find you want more variety, but having 3 motor sprockets gives you what's needed to test & see what direction to go next. We also provide a driven wheel sprocket that is custom bored to fit the included freewheel sprocket adapter. So you can disregard references to the missing "chainring". The image at the right shows the drive sprocket mounted to the freewheel, which is mounted directly to the wheel hub.

The Aerocoupe Assembly Manual suggests using bicycle sprockets and bicycle chain which isn’t included in the kit ordered from SHIFT EV. Bicycle systems stretch and more easily de-rail under the heavier loads and up-right configuration during corners in competitions. The Assembly Manual produced by the chassis manufacturer refers to a "Chain Ring" assembly to help the bicycle chain from de-railing. SHIFT EV ships the chassis kit without the chainring because it’s not needed. We've instead provided a superior drive system of go-kart sprockets and chains which are designed for rigorous loads and cornering - without derailing. We’ve also included 3 different sized motor sprockets to help you find the optimal drive ratio. You may find you want more variety, but having 3 motor sprockets gives you what's needed to test & see what direction to go next. We also provide a driven wheel sprocket that is custom bored to fit the included freewheel sprocket adapter. So you can disregard references to the missing "chainring". The image at the right shows the drive sprocket mounted to the freewheel, which is mounted directly to the wheel hub.

4. Break-in of a driven Aluminum sprocket on the rear wheel

Allow some time to properly wear in the newly machined 1821 sprocket. During wear-in (the first mile or so) avoid hard acceleration and check for slack in the chain and adjust if needed. Do not over-tighten the chain, or damage to the freewheel and other parts may occur.

5. SHUNT resistor location

It is a best practice to locate your shunt on the negative most end of your battery pack, as close to the battery (-) connection as possible. The shunt resistor is used to measure the current flowing from your battery pack. So force all power that exits your battery through it by connecting all negative power loads on the shunt side that is opposite from the battery (-) connection. When wiring the shunt and current measuring instrumentation such as Cycle Analyst, follow the printed instructions included with the Cycle Analyst.

6. Additional Fasteners and materials needed

6. Additional Fasteners and materials needed

As stated in our product description on our web catalog, other small materials may be required. We (SHIFT Electric Vehicles) have been unsuccessful in getting the Aerocoupe manufacturer to supply a single list. So we can only refer to what you see in the Aerocoupe Assembly manual, chapter by chapter for the additional materials such as nuts, bolts, rivets, etc.

7. Motor Controller wiring

7. Motor Controller wiring

A main contactor (also referred to as a solenoid or relay) is not required in most cases. Although some controller documentation may reference the use of one, and some competitions require one. A contactor consumes energy to operate, leaving less capacity to win a power-limited event like Electrathon and similar events. If your event rules require one, wire the controller according to the printed instructions that were packaged with your controller unit. If the rules don’t require a main contactor, such as Electrathon America, then we suggest you wire it as shown in the image below. Keep in mind that your controller shape and pin labels may be slightly different. If unsure, review the documentation provided by your controller manufacturer for your model before applying power to it.

Note: If wired properly, the motor controller will operate without the Key Switch Interlock (KSI), diode, foot switch, pre-charge resistor, and fuses. But each one of those has a safety and/or reliability function in exchange for only a few ounces. Use them unless you fully understand the consequences.

Note: If wired properly, the motor controller will operate without the Key Switch Interlock (KSI), diode, foot switch, pre-charge resistor, and fuses. But each one of those has a safety and/or reliability function in exchange for only a few ounces. Use them unless you fully understand the consequences.

8. Tips about fiber reinforced plastic wheels

The rim walls can spread from high tube/tire pressures. They don't have bead lock edges, so coarse scoring on the inside walls (like a record) may help the tire from moving or riding up the rim wall during inflation.

The rim walls can spread from high tube/tire pressures. They don't have bead lock edges, so coarse scoring on the inside walls (like a record) may help the tire from moving or riding up the rim wall during inflation.

- We have tested these rims (with appropriately rated tires) at up to 130PSI briefly without a load (for extreme flex measurements), but we recommend not exceeding 80PSI max (for tires rated 80PSI or greater).

- We have tested these rims (with appropriately rated tires) at up to 130PSI briefly without a load (for extreme flex measurements), but we recommend not exceeding 80PSI max (for tires rated 80PSI or greater).

- Do not pressurize tires from flat while the vehicle weight on the tire, or the tire may seat on the rim off-center.

- If the pressurized tire is off-center, mark the low spot with a piece of masking tape on the rim. Then reduce pressure and gently work the tire toward the low spot and re-pressurize. Repeat until the tire is centered.

- For storage, drop the pressure to 30PSI or less.

| Document Version | Date of Issue | Author(s) | Change(s) |

| A | 03/07/2017 | KS | As released. |

| B | 03/09/2017 | KS | Added battery box trimming option; added shunt and battery fit; added fasteners section; revised wording on other sections. |

| C | 03/15/2017 | KS | Added further description to #2 (throttle pedal mounting). |

| D | 03/20/2017 | KS | Combined what was 1 & 2 regarding throttle; added hilariously crude image explaining the basics of throttle mechanical assembly. |

| E | 05/04/2017 | KS | Added link to helpful pot box video to section 1. |

| F | 05/16/2017 | KS | Added section 8 "tips about fiber reinforced wheels"; edited section 2 regarding controller comments; Added section 9 about Switch/Circuit Breaker; Added links to twist grip and thumb throttle. |